Defects in metal forming springback effect in bending after plastic deformation there is an elastic recovery this recovery is called spring back.

Defects in sheet metal forming process.

Chapter 6 sheet metal forming.

If the temperature of the metal is above its recrystallization temperature then the process is.

The sheet metal forming parts will collide with the surrounding objects in the process of raw material.

The concept is similar to the rolling of dough rolling is classified according to the temperature of the metal rolled.

As a result during the product development process much attention is paid to avoiding defects on surface appearance and the resulting surface quality.

Identifying and resolving the most common defects in sheet metal forming solving common defects in sheet metal forming.

How to prevent them.

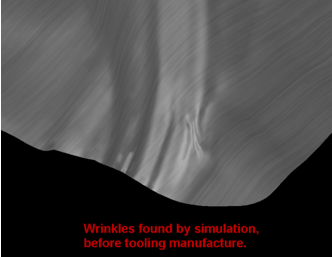

Wrinkles splits and springback are the three most common defects.

Surface defects is an important issue in sheet metal stamping as the stamping process affects surface appearance and thus influences surface quality.

The elastic deformation of mill takes place on the metal so some of rolling defects are provided in the metal forming.

There are two reasons.

Another common defect in sheet metal rolling involves the splitting of a workpiece.

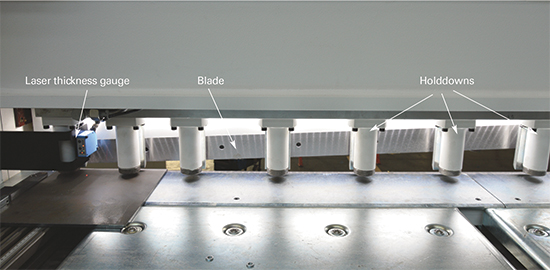

Sheet metal stamping dies amp processes manufacturing.

Sheet metal forming 2 810.

The surface unevenness is mainly caused by the unqualified stamping die.

Spring back can be calculated approximately in terms if radii ri and rf ri rf 4 ri y et 3 3 ri y et 1 spring back increases as r t ratio yield stress of material increases as elastic modulus e decreases 14.

The rolling defects are mainly two types.

Generally if experiencing wrinkles during production this could mean the wrong process was chosen.

A great amount of time is therefore spent during the product development process on the optimization of surface defects particularly surface lows during tryout.

During the rolling process a piece of metal will experience a different amount of reduction in certain areas of the piece.

Metal forming defects slideshare.

Sheet metal stamping defects lulusoso com.

How to prevent wrinkling during deep drawing thomasnet.

Describe different forming processes when they might be used and compare their production rates costs and environmental impacts calculate forming forces predict part defects tearing wrinkling dimensional inaccuracy and propose solutions.

The 6 52.

Stamping metalworking the full wiki.

In metalworking rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform.

This can cause an uneven roll with various amounts of pressure throughout the piece.